Drive for a prize is the most human thing uniting us all. The pursuit to achieve, accomplish, and acquire our deepest desires defines every action we take.

But, what do we do when we find the pot of gold at the end of the rainbow?

The answer remains, we catch with our eyes a space to make our own. Yes, infrastructure remains at the top of everyone’s minds and priorities to invest in. Always has been. Always will be. Now, with increasing job opportunities, access to better disposable income, increasing foreign investments, and globalisation, the demand and standards for infrastructure have risen. This is where things get interesting.

Construction, meet evolution.

The people of today, be it for residential, commercial, or any other purpose, have developed a vision for what passes as a desirable space to invest in. They want aesthetics and advantages. They expect the property to be energy-efficient, environmentally friendly, durable, long-lasting, and lightweight while strong enough to allow swift project completion without compromising on strength and support.

On the other side of this, we have builders and architects, facing the task of living up to these needs and desires, with their own set of challenges, such as:

-

Safety of the whole workforce

-

Reducing harmful emissions released into the environment

-

Conserving natural resources otherwise wasted

-

Not being able to meet the timelines as planned

-

Incurring extra expenses due to time, outdated materials, etc.

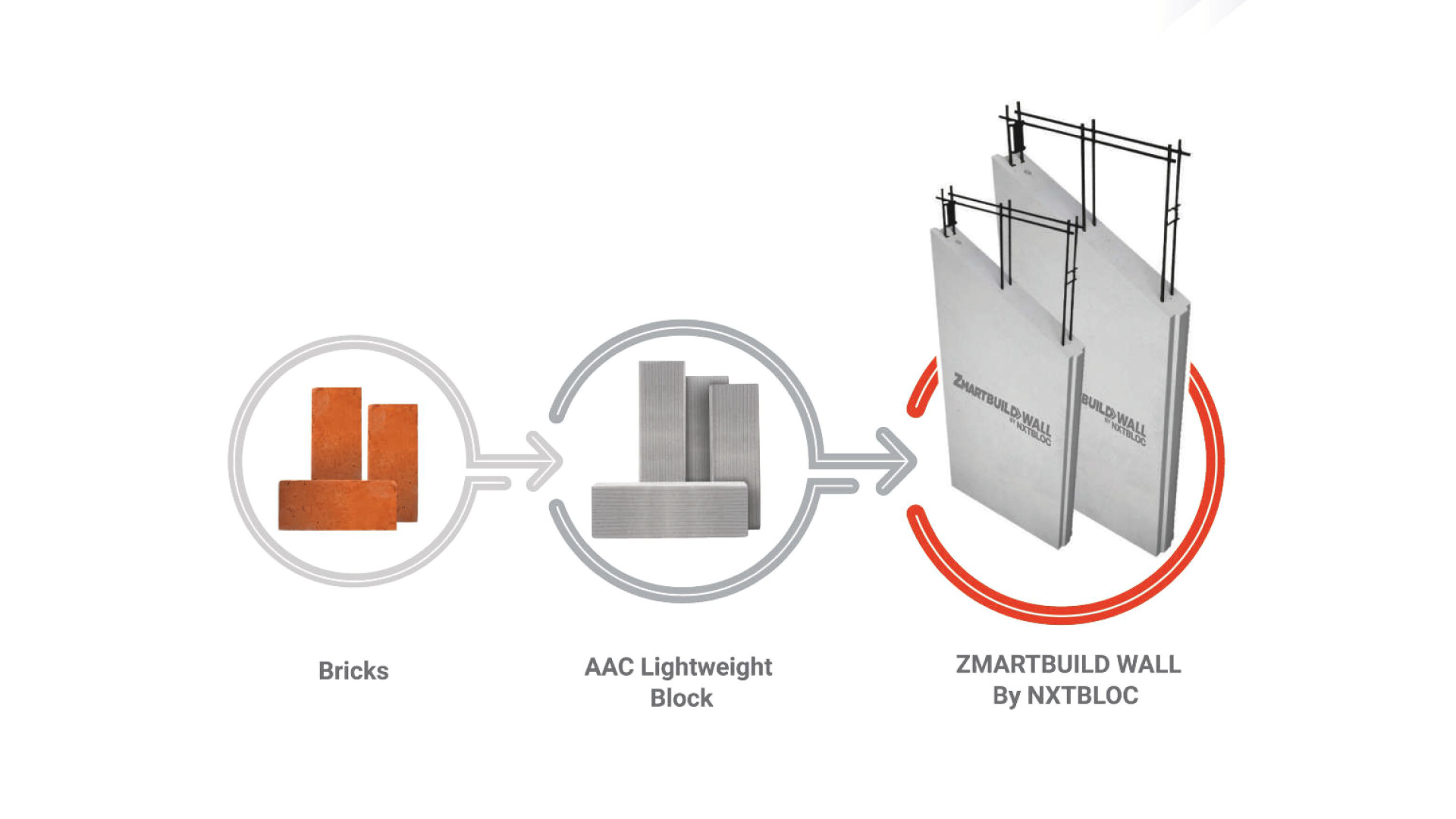

Coupling these two together brought new types of building solutions into the picture. Ones that delivered on every expectation. We are talking about prefabricated building solutions and other innovations.

Imagine a concrete wall, installed and completed in minutes, unlike taking days. Move aside, the idea of building brick by brick. It’s now possible with the AAC Wall. As India is set on the path to becoming the third biggest market for infrastructure, helping it grow are such future-ready building solutions. Like the Transparent Wood, Cross-laminated Timber (CLT), Self-healing Concrete, Aerogel, and more.

We dive in-depth into knowing the A to Z about the Autoclaved Aerated Concrete Wall (AAC Wall) and how this next-generation walling solution is equipped to deliver strength, safety, support, sustainability, and swift completion with its future-ready functions.

What Is An AAC Wall?

The Autoclaved Aerated Concrete Wall is also called a readymade wall or a precast wall. It is made with a special treatment of concrete. This Autoclaved Aerated Concrete Wall is a blend of natural elements and fragmented aggregates like cement, lime, water, and a small percentage of aluminium powder that get subjected to high-pressure steam curing. This treatment makes our Autoclaved Aerated Concrete Wall a lightweight, slick, yet sturdy walling solution with reliable support. To further cement its reliability, this Autoclaved Aerated Concrete Wall features a steel-reinforced build. It makes our Autoclaved Aerated Concrete Wall resistant to buckling and avoids deflection. This next-generation walling solution is one of the many prefabricated building solutions, mentioned earlier, dedicated to removing the hurdles of delay, maximising savings while optimising performance, and promoting safety on site. It achieves this by, like other prefabricated building solutions, being manufactured at factories away from the construction site. Then, our Autoclaved Aerated Concrete Wall, like other similar solutions, is brought to the site only for assembly. Leading to safer and swifter project completions.

History Of The AAC Wall

While our steel-reinforced AAC Wall remains a new development in the industry of building solutions, the heart of this innovation, the scientific treatment of concrete that is known as Autoclaved Aerated Concrete has been around since as far back as the 1880s. Back then, patents were rolled out for processes for aerating concrete using carbon dioxide and steam curing processes. Things started to shape into the process we know today in 1920. Swedish architect and inventor Dr Johan Axel Eriksson (1888–1961) and Professor Henrik Kreüger at the Royal Institute of Technology patented a process of making an aerated mix of limestone and ground slate that year. Later, Eriksson discovered that the moist foamed mass could withstand pressurised steam curing to quickly become a hardened structure. This process was also known as autoclaving. This process was patented in 1924 and began production in 1929.How Does An AAC Wall Work?

AAC Wall can become a popular choice for residential and commercial construction owing to low maintenance and many advantages.

Owing to the closed air pockets due to its composition, it weighs almost one-fifth of regular concrete and performs well in terms of sound insulation.

It works by reducing the dead load and composition time of a project by substituting the older, heavier, and clunky walling solutions, while never compromising on the performance. Get a complete understanding of its benefits as we proceed and learn how they give an edge to your projects.

Benefits Of Using An AAC Wall?

On top of saving on-site installers time and heavy lifting, our Autoclaved Aerated Concrete Wall helps you see how it stands in comparison to other walling solutions.

Lightweight:

Yet gives doubly high strength due to its steel-reinforced build with wire mesh ST50 and an anti-corrosion layer on the steel

Increased Carpet Area:

Slim & sturdy walls take up less space by covering only 7.5 cm, unlike 9 cm when using Drywall and 15 cm when using red bricks

Faster Installation:

6x faster project completion than traditional means because it does not require using a lintel for up to 6 metres and with our Certified Installers who can cover more than 30 square metres per day using it with just a team of 3 person

Steel-reinforced:

For flexural strength, safety & durability that conforms to the Indian Standards set under IS 6072

Low Finishing Cost:

Saves total cost by requiring less labour & time

Fire Resistant:

It is non-combustible & resistant for up to 2.5 hours in a wall with a thickness of 75 mm & for up to 4 hours in a wall with a thickness of 100 mm

Thermal & Acoustic Insulation:

Excellent at noise reduction with an STC (Sound Transmission Class) rating ranging between 37 – 43 & slowing heat transfer with 0.16 watts per metre Kelvin (w/mK)

Eco-friendly:

Reduces the consumption of water during installation by 98% than when using red bricks by using only 0.5 l/m2 as compared to red bricks that take 15 l/m2

Applications Of An AAC Wall

Our non-load-bearing internal and external walling solution successfully creates partitions in spaces made for any and every purpose. It successfully insulates and shields the following types of properties:

-

Residential Construction

-

Commercial Construction

-

Industrial & Warehousing

-

Institutional Buildings

-

Multi-storey Buildings

-

Renovations & Remodelling

-

Soundproof Construction

-

Green Building & Sustainable Solutions

AAC Wall Against Other Building Solutions:

Against Traditional Bricks:

While red bricks offer strong load-bearing support, they fall short when it comes to water absorption and being environmentally friendly. Their increased weight also leads to investing more manpower and time.

Against Concrete Blocks:

These solutions are strong and a popular contender when it comes to walling solutions. However, while they offer strength, seepage is their biggest weakness. They allow water to easily pass through and cause dampening and leakage.

Against Sandwich Walls:

Sandwich Walls, made up of three layers, a low-density core in the middle and thin skin layers, made up of concrete, at the top and the bottom, have limitations concerning load-bearing, UV rays, moisture, and more.

Against Drywall (Gypsum Board) Walls:

Drywall, a walling solution made using gypsum board (calcium sulfate dihydrate), paper, mica, clay, and resin, is known for landing convenience and efficiency as an interior walling or ceiling solution. However, they have a less durable core, which makes them prone to damage from impacts and tears.

Stay connected with us to learn more about advancements in building solutions and find the one that best fits your purpose for a truly worry-free experience.