Fibre cement board VS Wood cement board

- April 18, 2019

- , 3:02 am

- , Product Guide

“Fibre cement board and wood cement board are both cement board materials but they are different in some aspects which home owners should know in order to make a good decision when choosing them. ”

When we talk about board materials for houses such as ceiling, wall and flooring boards, we are always familiar with plywood and gypsum board. However, there are some more materials in the market known as “cement board” which can be categorized as fibre cement board and wood cement board.

Getting to know more about cement board

Cement board is made of “Portland cement” (strong material which can be brittle if being pressed into thin sheet) mixed with other flexible materials and compressed with high pressure into board. This material is strong but flexible, termite-resistant and water-resistant to some extent. Materials to be mixed with cement determine type of cement board. If cellulose from trees is mixed with silica, the material will be called “Fibre Cement Board”. If wood chips are mixed with cement, the material will be called “Wood Cement Board” or Cement Bonded Particle Board.

How fibre cement board and wood cement board are different from each other?

Both of them share some similar qualifications such as being used as internal and external flooring materials, light wall, ceiling board and roofing lining materials. They are low in heat conducting so they are ideal for energy saving houses. However, they are different in deeper details due to differences in raw materials and production process.

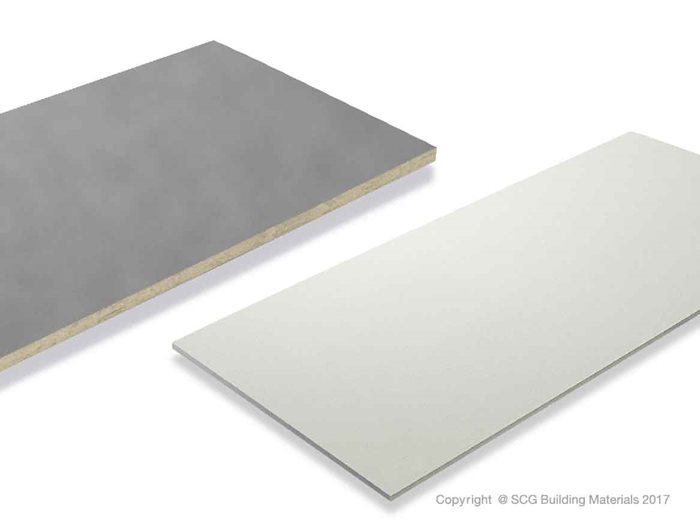

“Wood cement board” is made of cement mixed with shredded wood chip compressed into board. Its core is strong while its surface is smooth. As for “fibre cement board”, it is made of cement mixed with cellulose and silica making it strong and durable. Moreover, with special compression technique, the board is slim. When comparing cross sections of these 2 products, it is found that fiber cement board looks smooth while wood cement board offers different textures between internal area and surface.

Major component like cellulose fiber makes fibre cement board slimmer and lighter than wood cement board (made of shredded wood chip). This difference is obviously seen when being used for the same purpose, for example, fiber cement board ceiling is only 3.5-4.0 cm. thick while wood cement board is 8.0 mm. Therefore, ceiling section must be considered to be especially strong. In addition, care should be given to crack on screw head. In case of being used as flooring material, fiber cement board will be 16 or 18 mm. thick while wood cement board will be 20-24 mm. So, structure must be able to accommodate higher weight etc.

Different gimmicks

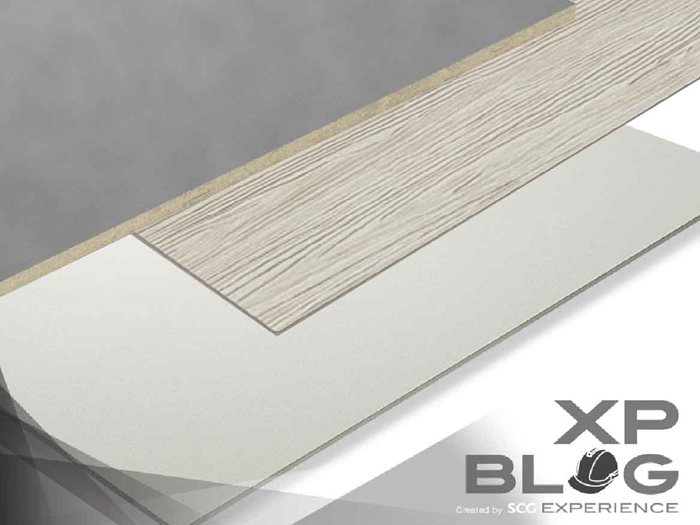

Wood cement board cannot be bent while fibre cement board can due to length and flexibility of its component or cellulose fiber. Radius of bending depends on thickness of fiber cement board. There is variety of choice of surface to select. Apart from even surface, gouged and wooden surfaces are available. Some are already painted and some have ventilating hole which is suitable for ceiling and eaves. However, although wood cement board is good at smooth surface, there are choices of patterns such as wooden and stone surfaces to choose.

Touching up the surface

For even surface model, if empty surface is shown, coating agent should apply for durability. And for external use, seal must be applied to prevent dampness. Fiber cement board and wood cement board can offer several choices of surface decoration such as plastering, painting and spreading other materials on top. There may be some special techniques to learn from manufacturers before installing such as covering tiles on fiber cement board must be done on more rugged side.

As earlier mentioned, surface of wood cement board is smooth and even and looks like empty cement floor so it is always used to show its surface while naturally, fiber cement board surface is not as beautiful as wood cement board. So if you want empty cement surface style, you have to apply thin layer of grey cement on the surface. Fiber cement board can be installed in even plastered surface style. This can be done by using tilting rim model plastered with plastering material and fabric tape. However, with slightly rugged surface, after being plastered, the surface may not be totally smooth.

Learning about qualifications of these 2 types of cement boards, you will understand their differences and be able to choose more appropriately. Both of them offer safety advantages that should not be overlooked which are inflammable, flame-retardant and having no asbestos so they are non-toxic and non-carcinogenic. In brief, they are very interesting materials to choose for your house.

Share this post

Customer Service

Contact Us

Tel./Whatsapp +6681-848-0870

Email: info@zmartbuild.com

4 Comments

Dear Sir,

I am curious to know what standard is used to the fiber cement board production? and what composition of material to produce this composite?

Thank you in advance for your explanation.

Best regards,

Phouthanouthong

Hi Phouthanouthong,

Our fiber cement board production/properties are controlled in accordance with ISO 8336 Standard. The mainly composition are SCG portland cement ,Cellulose Fiber ,Sand and Water.

Thank you,

Hi, we are a small company based in Buriram making European Kitchens & built-in Bedroom furniture.

we have just bought some land & are about to build a new factor, & wish to expand the Kitchen side.

At present our Kitchens are made from melamine faced partical board or Plus wood but we would like to start using Cement board.

My Question is, which would be the best to use for Kitchens & built-in furniture, Cement Fibre Board or wood Cement Board. It needs to be completely water proof & termite proof.

Kind Regards

Ron

Hi ,Ronald

We are very appreciated that you’re interested our products.

May we have some information from you ,Which part of furniture you want to do?

Regards

Technical Team