Wall Crack root causes & How to deal with it?

- March 19, 2020

- , 6:15 am

- , Product Guide

- admin

“Less opportunity to occur wall crack shrinkage in your project with Zmartbuild Wall Panel”

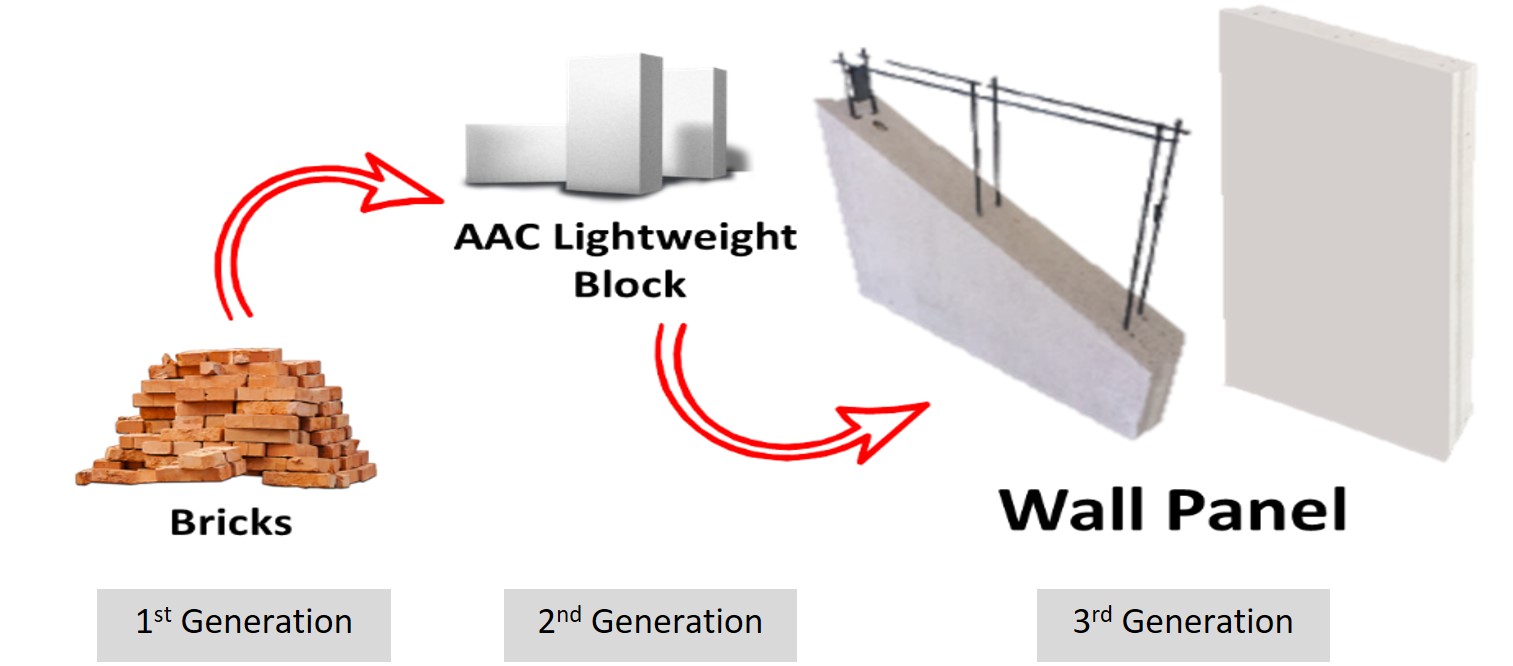

Once builders and contractors in India have to build wall and partition work, traditional brick and AAC Block are usually materials that have been selected to use. As they are well acquainted with these materials for long time and it is easy to get from the market. Because there are many producers and suppliers.

However, most developers and project managers often experience or encounter the problems on wall after completion of project, especially “the wall crack from shrinkage”.

This crack makes project owner to be nervous and anxious owing to easy to get the claim from their customers. Then they should know how to reduce the chance of having wall crack from shrinkage. Or which materials should be used in order to have less opportunity to have this type of wall crack.

Firstly, developers and project managers should grasp all types of wall crack and their root cause. In order for them to be acquainted with another materials besides clay bricks and AAC Blocks.

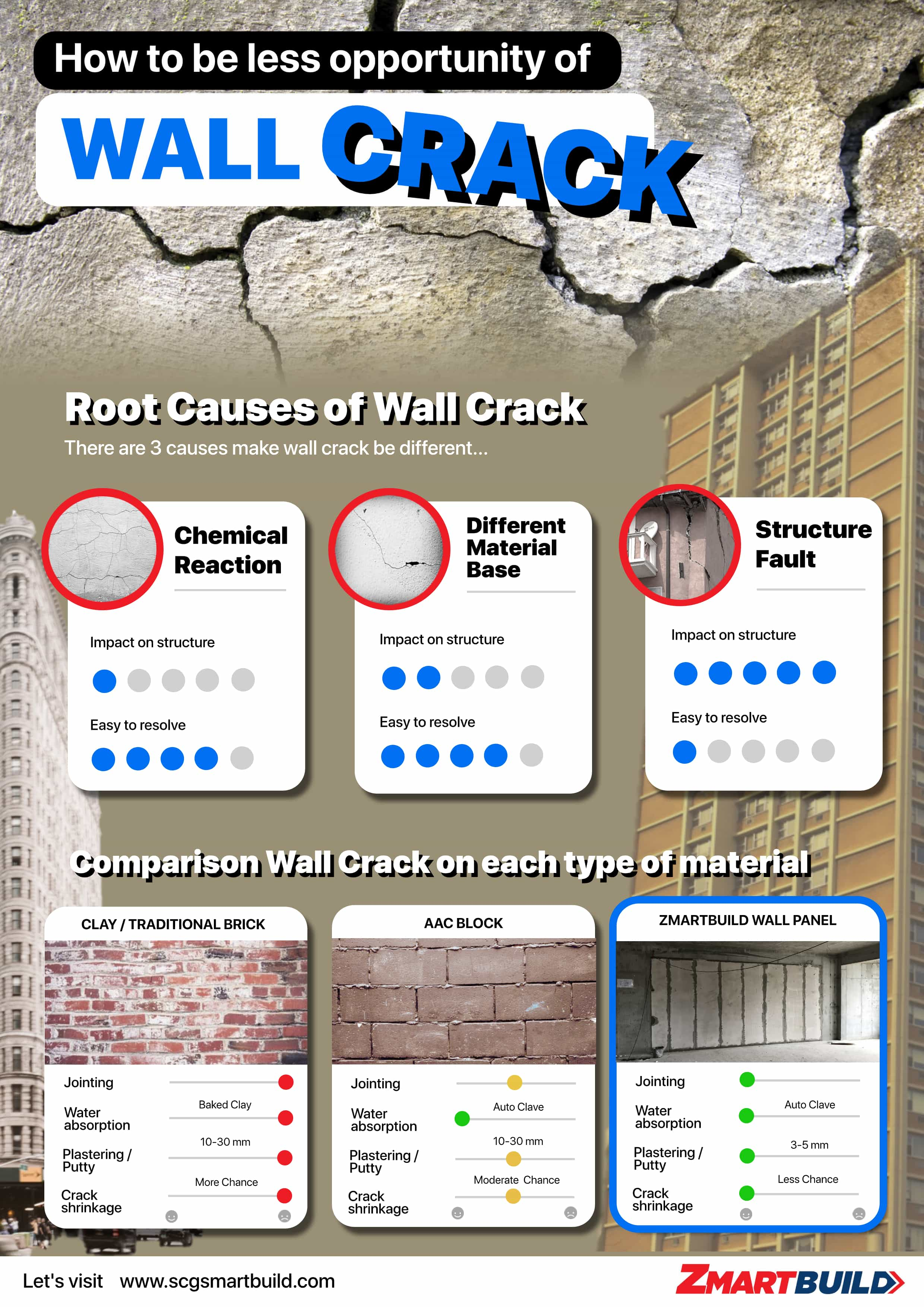

What are Root Causes of Wall Crack?

Most Developers and Project managers used to experience or face the wall crack problems. And need to know their root cause in order to analyze and find the way to solve these issues. Wall crack has many causes then the corrective ways which will be different depends on the cause of the cracking.

The cracking which will take place more or less depends on the material used for the construction, the climate, the working method during the construction. Including labor skill and the expansion and the sacking of the structure in that area. There are three main causes of wall crack as following.

1. Chemical Reaction

It can cause the small cracks on interior and exterior wall, column and wet area. These cracks are caused because the water used to mix with the plastering mortar is lesser. Plastering mortar cannot ventilate the heat. When the plastering mortar becomes set, it will have the chemical reaction which causes the high heat until there are some cracks on the plastering wall. Nevertheless, these cracks will not have the impact on the structure of the building. But it will have the effect only on the exquisite surface of the building.

If the cracks are not deep, they can be fixed by using the Putty to bond the jointing parts and painted one more time to complete the job. This type of cracking may come from the hot climate which makes the water evaporated slower than the chemical reaction in the plastering mortar which finally causes the cracks as well.

2. Bonding of the plastering wall with other materials

The cracking comes from the expansion and the shrinkage of different material base because each material will have different ratio of bonding. Furthermore, the external wall outside the building will have the higher temperature than the internal wall. Therefore, the elasticity and shrinkage of the wall for both sides will change differently which will incur the wall crack.

These small cracks can come from the window frame or the door frame in the horizontal, vertical and diagonal direction.

3. Building structure

This type of cracking does not take place often. However, if it takes place, it is due to the piling foundation, beam and the natural collapsing. Or the natural subsiding of the ground or the soil or the moving of structure owing to natural disaster e.g. earthquake and heavy storm for instance. It will get deep inside the wall until the bricks for both sides can be seen inside.

The correction requires the specialized structural engineer to analyze and figure out the root cause. As it will have an impact on the loading capacity of the other parts of the building.From these aforesaid causes, most of the wall crack found come from the chemical reaction, installer’s skill and the shrinkage of wall.

Comparison Wall Crack on each type of material

Let’s see the likely chance for the shrinkage crack in wall by building materials. There are three types of materials for comparison.

1. Traditional bricks:

Clay brick is likely and mostly to have the crack shrinkage because the body material comes from the soil, husks and ash which will be burnt together. The plastering mortar will have the thickness for each side of the bricks around 1 cm.

When plastering, hence it makes the ratio of water absorption higher as well as the smaller size of bricks bring to a result it requires more units of bricks per one side of the wall. So there will be more jointing and connecting area between panels.

It is likely that the wall will not be straightened and the wall will be fallen down easily. Those installers must plaster wall with mortar for more thickness in order to make wall stand straight on same level. As a result, heat transfer of mortar is not good enough which can lead to the higher chance of shrinkage crack in wall.

2. AAC Blocks:

This material will have less chance to have the shrinkage crack in wall problems than the traditional clay bricks. Because the material used come from the lightweight concrete which goes through the autoclave process.

It absorb less water from the plastering mortar because such an autoclave process will accelerate the chemical reaction and the usage of water in AAC Blocks has almost completed. Therefore, it does not absorb more water from the plastering mortar than traditional clay bricks. Whereas still have some water absorption because of the small holes in AAC Blocks.

In addition, if you consider the size per unit of AAC Block with the clay bricks. Although AAC Blocks will have the bigger size per unit than the clay bricks. The installation of one side of the wall requires more units.

AAC Block makes more connecting and jointing areas which is likely that the wall will not be straightened and the wall will be fallen down. If the installer is not specialized in the installation of the wall. And needs to plaster the wall with the mortar for more thickness which is similar to the construction of traditional clay bricks. So the heat transfer of the wall is not good enough. Wall crack from shrinkage will be likely to take place also.

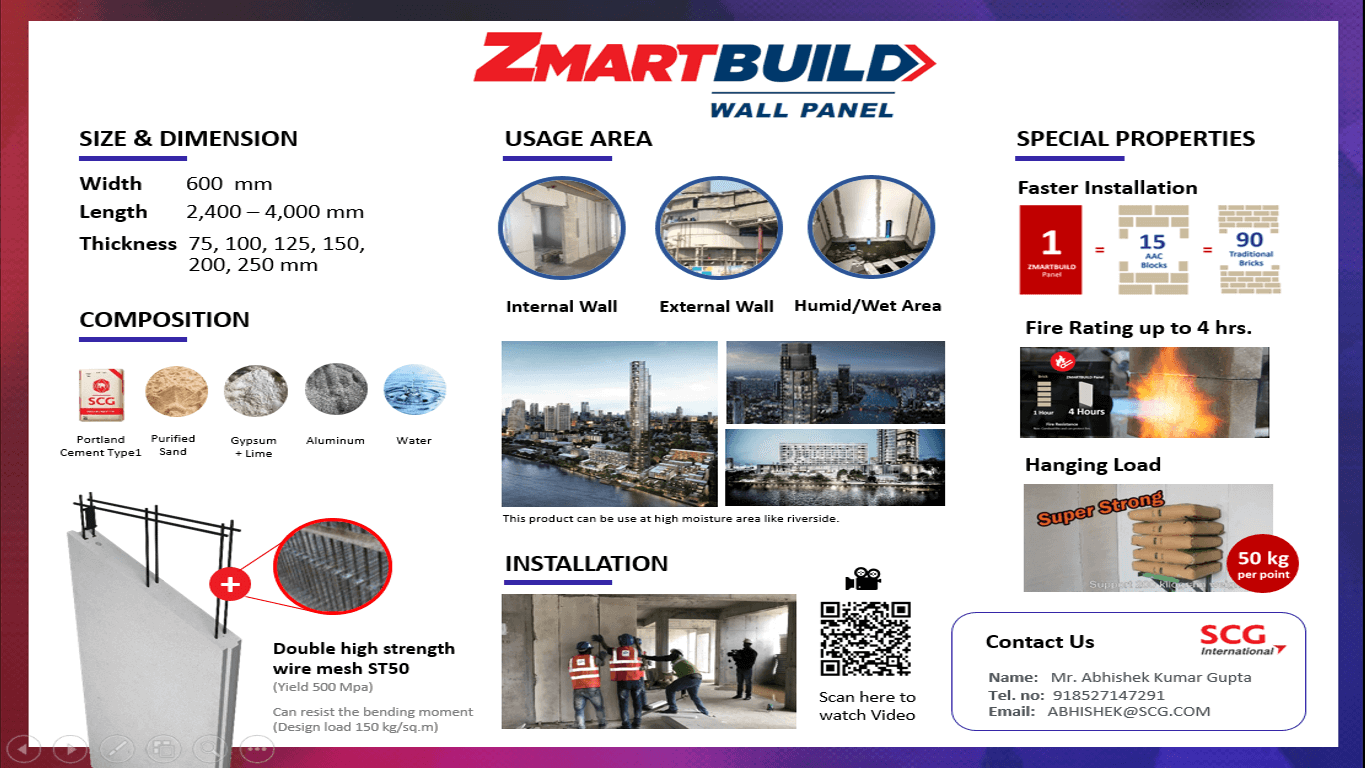

3. ZMARTBUILD Wall Panel :

Has the same material as AAC Blocks but with the bigger size of the material in one piece from the ground floor until the ground ceiling above. It affects to be few connecting and jointing areas.

Moreover, a number of panels per unit used are less when you compared to two materials aforementioned. Therefore, a number of connecting and jointing areas are less so the chance for the wall to be fallen down is less.

Then the plastering of wall will be skimming method with the thickness of only 3-5 mm. The heat transfer will be good when the mortar is set, it leads to less opportunity for wall crack from shrinkage.We, SCG Company from Thailand, would like to introduce this new solution “Zmartbuild Wall Panel” to India market. It is the 3rd generation of wall material which can be help your project will save more total cost, faster construction 4 times than AAC Block and reduce opportunity of wall crack from shrinkage.

Our Zmartbuild Wall Panel is trusted product quality that is proved by over 3,068 projects around the world. Including mega projects in Thailand like Siam Paragon, Luxury shopping mall and Terminal 21 Korat, etc.So we are pleased to be the trustworthy manufacture who bring the good quality and innovative product to India market. Do not hesitate to contact us if you need more information.

Contact us to ask Price or Coverage area of Zmartbuild Wall Panel. Click>> Whatsapp me now!

Others:

- More detail of Zmartbuild Wall Panel >> ZMARTBUILD WALL PANEL

- Download catalog >> ZMARTBUILD WALL PANEL Catalog

- Installation VDO clip >> Watch ZMARTBUILD WALL PANEL installation

Related Product

Share this post

Customer Service

Contact Us

Tel./Whatsapp +6681-848-0870

Email: info@zmartbuild.com